large and medium-sized furniture factories

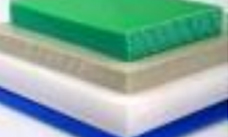

edge banding processing of aluminum sealing panel

PET high gloss door panel

aviation panel

bamboo Kun board

PVC board

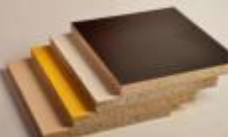

medium density fiberboard

blockboard

solid wood board

particle board

polymer door panel, plywood

| Type | MD-886SKKL-PURS |

| Touch screen | 15 |

| Electric lifting | automatic |

| Working presure | 0.6MPA-0.8MPA |

| Total power | 28KW |

| Overall size | 12100* 1000*2000mm |

| Feeding speed | 13-18-26m/min |

| Panel width | ≥100mm |

| Panel thickness | 10~60mm |

| Edge width | 15~65mm |

| Edge thickness | 0.4-3mm |

| Weight | 4800KG (around) |

Touch screen 10 "HD large screen

The woodworking industry's leading touch screen, fast response, do not miss touch.

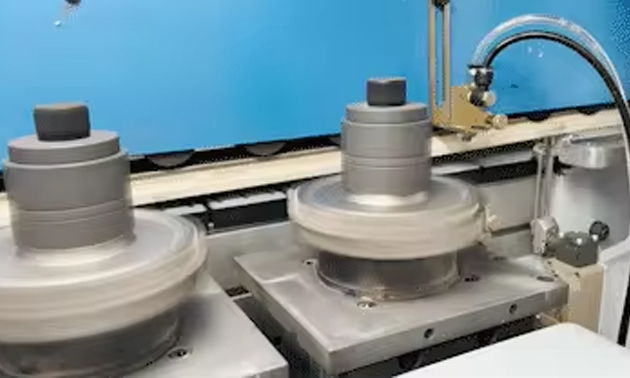

Pre-milling

The diamond pre-milling cutter milled the corrugated marks and excess burrs of the spiral trimming knife to make the edge of the board more fit to the edge sealing strip, and the bonding is more firm and more beautiful. Pneumatic control of the pre-milling seat, more accurate, more convenient control.

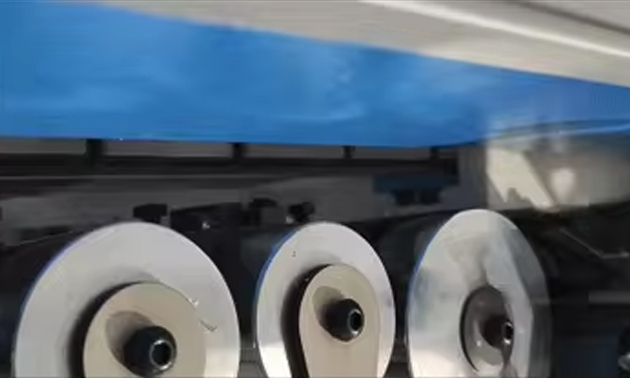

Crawler Pressing

Make the sealing strip fit the plate surface, the rubber wheel belt elastic, better adhesive force.

Six wheels pressed with rubber wheelng

Make the sealing strip fit the plate surface, the rubber wheel belt elastic, better adhesive force.

Fine Trimming

The 6-blade R knife trims the excess sealing strip to form a rounded corner, and the trimming is more beautiful.

Prev : none

Next : none