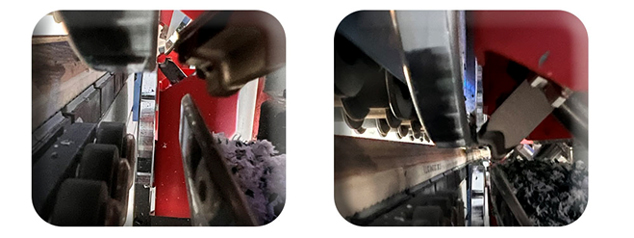

Regular cleaning: The first step in automatic edge banding machine is to clean up the waste and debris generated during the machine's production process to prevent waste buildup that could cause the machine to jam, affecting work efficiency. Additionally, it is essential to clean various stains on the machine surface to maintain its aesthetic appeal and prevent corrosion.

Maintain the appropriate workshop temperature: The temperature during the operation of the automatic edge banding machine should not be too high or too low. Extremely low temperatures can cause the machine oil to freeze, leading to operational issues, while excessively high temperatures can hinder heat dissipation, potentially damaging the motor.

Computer maintenance: Nowadays, most automatic edge banding machines are connected to computers for automated programming. Poor computer maintenance during operation can lead to lagging or system crashes, impacting the machine's efficiency and performance.

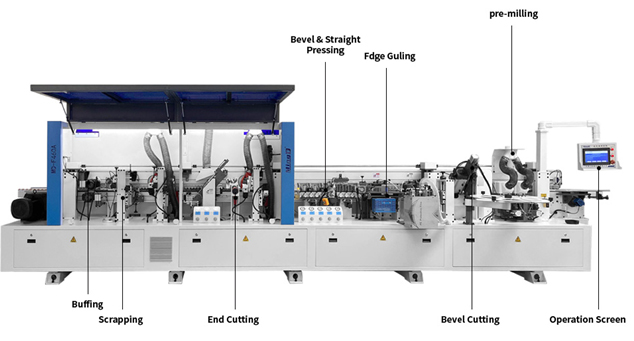

Installation steps for Automatic Edge Banding Machine:

1.Unpack and remove the packaging of the fixed mechanical components.

2.Place the machine on the ground and ensure it is leveled.

3.Securely install the coil edge banding material on the machine using the storage turntable.

4.Connect the external power supply, 220V 50HZ three-phase four-wire power supply, with a total power line diameter of at least 4 square centimeters.

5.Connect the air supply.

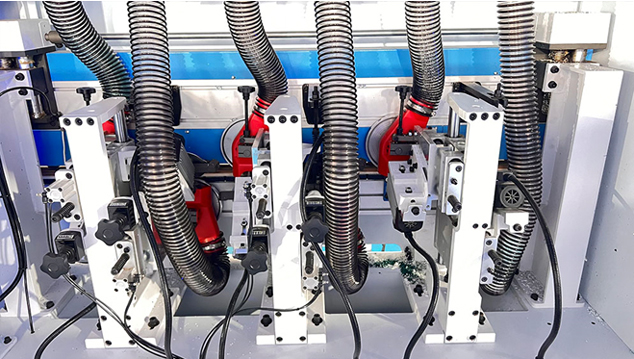

6.Connect the dust extraction pipe to the dust removal equipment.

7.Check the voltage to ensure it is normal and ensure an adequate supply of compressed and dry air.

Guangdong Shunde Mingdiao Electromechanical Equipment Co., LTD., founded in 2013, is a professional R & D, production of high-end CNC cutting machine, CNC drilling and miling machining center, automatic edge banding machine, automatic production line equipment, woodworking drill and other equipment enterprises.

Prev : none

Next : none